Machine Consulting and Training for Flexible Packaging Excellence

Unlock Precision, Efficiency, and Cost Savings in Your Packaging Operations

Flexora Equipment Consulting and Training specializes in optimizing flexible packaging operations—from flow wrapping to VFFS and pouch converting. We help manufacturers and co-packers reduce waste, boost efficiency, and improve product quality through expert training, machine consulting, and production system design—one operation at a time.

Contract Packaging

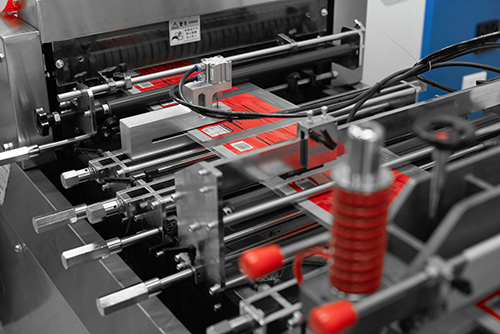

Flow Wrapping Machinery

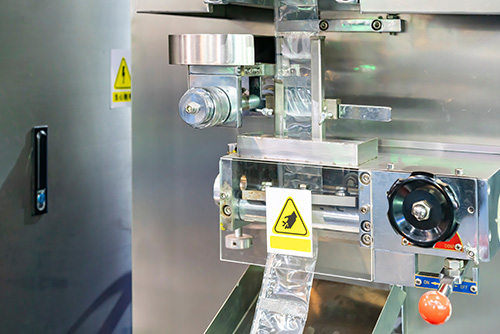

Vertical Form Fill and Seal (VFFS)

Reduce Waste, Headaches and Increase Profitability!

Machine Consulting

- Equipment Assessment: Evaluate your current machinery setup to identify inefficiencies and recommend upgrades or adjustments.

- Process Optimization: Develop customized workflows to control critical variables like tension, speed, and alignment for consistent output.

- Technology Implentation: Advise on integrating servo motors, frequency drives, and potentiometers to enhance precision and automation.

Troubleshooting Support: Diagnose and resolve issues related to machine performance, seal quality, and production bottlenecks - Quality Control Implementation: Flexora offers a full quality system for converting films into pouches or flow wrap applications your company can utilize

- Standardized Testing Protocols: Implement proven methods for testing air leaks, seal strength, and seal integrity to meet industry standards.

- Quality Assurance Systems: Design systems to monitor and maintain pouch quality, reducing defects and ensuring customer satisfaction.

- Data-Driven Insights: Use testing data to identify trends, improve processes, and maintain compliance with regulatory requirements.

Operator Training Programs

- Customized Training Modules: Deliver hands-on training on machine operation, maintenance, and troubleshooting tailored to your equipment and processes.

- Skill Development: Equip operators with the knowledge to manage servo motors, tensioning systems, and frequency drives effectively.

- Safety and Compliance: Ensure operators are trained in best practices for safe operation and adherence to industry regulations.

Process Development for Scalability

- Workflow Design: Create standardized processes for contract packaging, flow wrapping, and VFFS operations to support scalability and efficiency.

- Downtime Reduction: Implement preventive maintenance schedules and machine calibration protocols to minimize disruptions.

- Continuous Improvement: Establish feedback loops to refine processes and adapt to evolving production demands.

Comprehensive Production Management Systems

- Production Management: Implement full systems for live production tracking, enabling real-time monitoring of output, efficiency, and machine performance.

- Waste Control: Design strategies to minimize material waste, optimize resource usage, and reduce costly production errors.

- Quality Auditing Records: Develop robust record-keeping systems for quality audits, ensuring traceability and compliance while preventing product rejections.

- Cost Savings: Our integrated systems can save hundreds of thousands of dollars by reducing wasted goods, minimizing rejected products, and improving overall operational efficiency.

Our Expertise

Machine Consulting

Expert guidance to streamline your packaging processes and boost efficiency.

Quality Control Standards

Implementing standardized testing for air leaks, seal strength, and seal integrity to ensure consistent, high-quality pouches.

Operator Training

Developing robust training programs to equip your team with the skills to operate, troubleshoot, and maintain complex packaging equipment.

Process Standardization

Creating repeatable, efficient processes to minimize waste, reduce downtime, and enhance productivity.

Machine Optimization

Mastering machine variables, mechanical functions, servo motors, frequency drives, potentiometers, and tensioning systems for peak performance.

Production Management Systems

Designing integrated systems for production tracking, waste control, and quality auditing to maximize efficiency and profitability.

Proven Expertise:

Deep knowledge in pouch converting, quality control, and advanced machinery systems honed through years of industry experience.

Tailored Solutions:

Customized consulting, training, and production management systems designed to address your unique challenges and goals.

Results-Driven Approach:

Focus on measurable outcomes, including improved pouch quality, reduced waste, increased production efficiency, and significant cost savings.

Comprehensive Support:

From initial assessment to ongoing training and system implementation, we partner with you to ensure long-term success.